INDUSTRIOUS

ISLANDS

The Right Chemistry

Innovative industries have been able to use the islands’ natural resources in sustainable ways which have protected the environment, if not always the people.

The 1800s saw a growing kelp industry across the islands, where seaweed was collected, dried, burned and then the ash was shipped for use in the chemical, soap and glass industries. It was a painfully hard industry for the local people who worked long hours in extreme conditions for little reward.

In comparison, it was very lucrative for the landlords of the time until it crashed in the 1840s due to cheaper imports. The alginate that the kelp produces can be used as a thickening agent in toothpaste, jelly and ice cream.

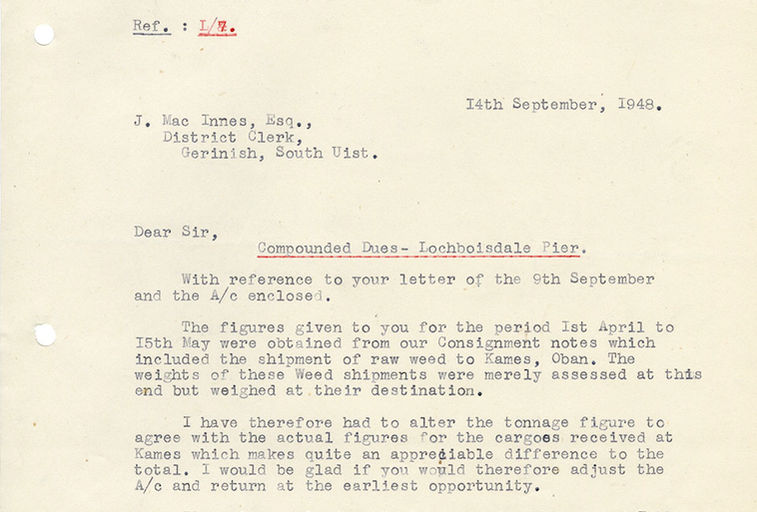

Although Alginate Industries Ltd first arrived in Uist in 1944, it wasn’t until 1968 that it truly regenerated the local seaweed industry. The firm processed seaweed collected in the Hebrides, Orkney and Shetland and exported the extracted alkali and acids to around 80 countries. That year they won the Queen's Award for Industry for export achievements.

Pharmaceuticals is a newer industry in the Outer Hebrides, but have now been produced here for 35 years. The Breasclete Factory on Lewis is now owned by BASF - the world's largest chemical manufacturer. The factory make natural pharmaceutical products and specialise in lipid chemistry and omega-3 fatty acid production.

The Lewis Chemical Works

The Lewis Chemical Works, or Stornoway Paraffin Works, was originally set up in 1857 by Sir James Matheson who owned Lews Castle at that time. It stopped production 17 years later. Similar to the kelp industrial process, the Chemical Works dried and distilled a local resource which the local people gathered.

In this case it was peat which was used to produce tar in a liquid, gas and solid state. The main product produced by the Chemical Works was paraffin.

Video Gallery ::

A Brief History of Lewis Peat

BACK TO THE TOP